Air cooled double-head screw chiller

Description

The DY-FSQ series industrial screw chillers adopt famous, nice quality and brandnew screw compressor and the high efficiency evaporator and condenser, make them have big and good cooling effect. They are widely used in large refrigeration occasion and concentrated cooling areas. They always used as the host machine of central air conditioning project and other civil and industrial fields. For example:

For civil field: commercial buildings, entertainment centers, hotels, hospitals, theaters, stadiums and shopping malls etc.

For industrial field: plastic and rubber, pharmaceutical, textile chemical, food and beverage, electroplating and electronic industry etc.

Models: DY-FSQ100A

1. The energy efficiency degree has already been above the first level of national energy efficiency index.

2. Working stably, safely and reliably under the environment temperature of 0~45℃.

3. PLC Microprocessor control--easy to operate, accurately control temperature range from 3~50℃. Precision: ±0.1℃

4. Brandnew imported famous brand Semi-screw compressor, which ensures the efficient and stable operation of the chiller, that makes it has a longer service life, which generally can be used for 5 to 10 years.

5. The EER/COP is high, so it is more energy-saving than the general scroll type chiller.

6. Imported famous brand high-quality spare parts and domestic industry leading parts to ensure better performance for the chiller.

7. Own brand independently designed and developed high efficiency condenser and evaporator to ensure super refrigeration.

8. Frequency high power, big air flow rate and low-noise cooling fan--ensures nice heating dissipation

9. Well designed and reasonable pipelines--ensures power supply and saves energy.

10. Intelligent PLC touch screen control display--shows temperatures of outlet and inlet chilled water and each specific Error on(It is clear to know each Error) and provides visualized and direct setting; Can touch the screen to set and check the info.

11. Industrial designed-elegant and ergonomic.

12. Multiple protection functions ensure the comprehensive protection for chiller.

| Cooling capacity | kw | 280.4 |

| ton | 79.73 | |

| kbtu/h | 956.67 | |

| kcal/h | 241424.4 | |

| Total input power (kw) | 85 | |

| Max running current (A) | 145.7 | |

| Power supply | 3Ph 380V 50HZ(200V/220V/415V 460V 50HZ/60HZ, customized) | |

| Refrigerant | Type | R22(R407C) |

| Charge volume (kg) | 70 | |

| Control method | Outside balance thermal expansion valve | |

| Compressor | Type | Semi-hermetic screw |

| Power (kw) | 78 | |

| Start-up mode | Y-△ | |

| Running current (A) | 131.2 | |

| Capacity control | 0-33%-66%-100% | |

| Evaporator | Type | Shell and tube type with internal thread |

| Chilled water flow rate (m³/hr) | 46 | |

| Heat exchange (kw) | 280.4 | |

| Condenser | Type | High Efficiency Copper Aluminum Fins |

| Fan type | High-power axial fan | |

| Fan motor power (kw) | 7 | |

| Fan current (A) | 14.5 | |

| Heat exchange (kw) | 336.4 | |

| Fan diameter and quantity (mm*pcs) | 600*10 | |

| Cooling air flow rate (m³/hr) | 118000 | |

| Inlet/Outlet pipe diameter (mm) | 125 | |

| Mechanical dimensions (mm) | 4000*1800*2100 | |

| Unit weight (kg) | 2750 | |

| Operating weight (kg) | 3300 | |

|

Has multiple protection functions: a. Abnormal temperature protection, low circulating water temperature alarm and cut off the compressor b. Power reverse phase protection, power phase detection to prevent pump and compressor from reversing c. High and low pressure fault protection, the pressure switch detects the pressure state of the refrigerant system d. Compressor overload protection, thermal relay to protect the compressor e. Compressor overheating protection, internal protector to protect the compressor f. No fuse switch disconnection protection, no fuse switch tripping g. Low water flow alarm, water flow switch h. Short circuit protection, air switch disconnected i. Abnormal discharge temperature protection, high discharge temperature alarm and cut off the compressor |

||

| Remark: Unit conversion for cooling capacity | ||

| 1ton=3.517kw | ||

| 1kw=861kcal/h | ||

| 1kbtu/h=0.2931kw | ||

| Notes: | ||

| 1. The cooling capacity is based on the chilled water inlet temperature 15℃, outlet temperature 10℃; Cooling inlet air temperature 35℃, outlet air temperature 40℃. | ||

|

2. Working range: a. Temperature range of chilled water: 3~22℃; Temperature difference between inlet and outlet of chilled water: 5℃ b. Cooling temperature range: 35~40℃; Temperature difference between inlet and outlet cooling air: 5℃. |

||

|

Please kindly take some time to check the notes, if you find the above specification is different from your requirement, just let us know the following information, the suitable model chiller will be provided to you soon. 1. The cooling capacity of chiller 2. Chilled water inlet temp and outlet temp 3. Cooling water inlet temp and outlet temp 4. Water flow rate 5. Refrigerant gas type 6. Power supply: voltage/frequency/phase 7. Ambient temperature 8. Chiller will be used in which field |

||

Industrial use

-

Dust free workshop

Dust free workshop

-

Electronic components industry

Electronic components industry

-

Extrusion industry

Extrusion industry

-

Food and beverage industry

Food and beverage industry

-

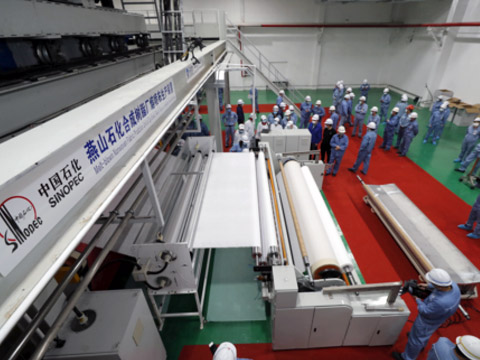

Nonwovens industry

Nonwovens industry

-

Pharmaceutical industry

Pharmaceutical industry

-

Plastic rubber industry

Plastic rubber industry

-

Printing industry

Printing industry

Civilian use

-

Commercial building

Commercial building

-

Gymnasium

Gymnasium

-

Hospital

Hospital

-

Hotel

Hotel

-

Library

Library

-

Museum

Museum

-

Opera house

Opera house

-

Shopping mall

Shopping mall

Related Products

- About Us

- Company Profile

- Our Culture

- Enterprise Honor

- Factory Tour

- Powerful Industry Strength

- Video

- Download

- Products

- Industrial Cooling Series

- Mold temperature control series

- Plastic crushing & recycling series

- Mixing Series

- Drying & Dehumidifying Series

- Feeding & Conveying Series

- Solutions

- Central Cooling System

- Drying And Dehumidifying System

- Crushing And Recycling System

- Central Feeding System

- Extrusion Blow Moulding System

- PET Preform System

- Contact Us

- Email: info@dgdinyuan.com

- TEL: +86-769-83503283

- Add: Building B First Floor No.3 Xinglong 2nd Road xiaxu Village Changping Town Dongguan City Guangdong, China